Aluminum Silicon Carbide (AlSiC)

Lightweight Strength for Thermal Management

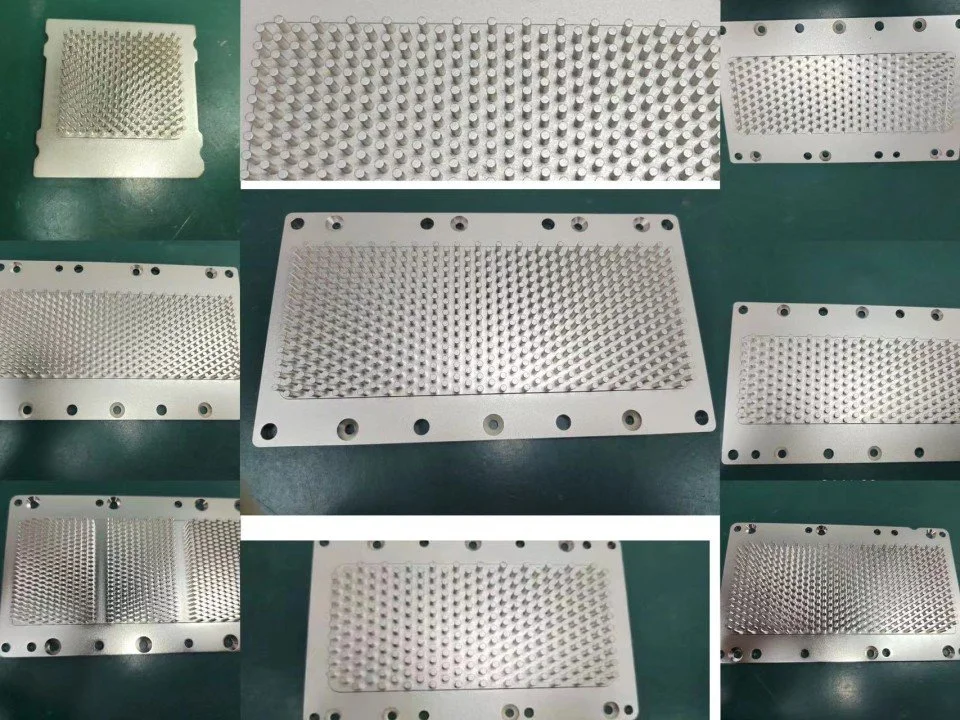

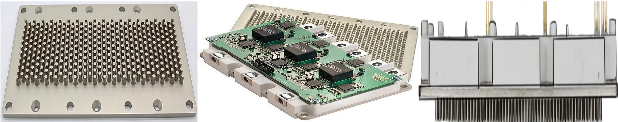

Aluminum Silicon Carbide (AlSiC) is an advanced metal matrix composite combining the lightweight, high thermal conductivity of aluminum with the exceptional stiffness and low thermal expansion of silicon carbide. This unique combination delivers superior mechanical stability, excellent heat dissipation, and a close match to semiconductor device materials — making AlSiC an ideal choice for high-performance electronic packaging and structural applications.

Specifications

Matrix Material: Aluminum alloy (6061, 7075, or custom)

Reinforcement Material: Silicon Carbide (SiC) particles (monocrystalline or polycrystalline)

SiC Volume Fraction: 25–70% (customizable for thermal and mechanical properties)

Thermal Conductivity: 170–230 W/m·K (matches silicon chips for thermal management)

Coefficient of Thermal Expansion (CTE): 6–10 ppm/K (tailored to minimize thermal stress)

Density: 2.7–3.0 g/cm³ (lightweight, near aluminum)

Tensile Strength: 300–500 MPa (2x unreinforced aluminum)

Operating Temperature: -40°C to 400°C (robust for high-temperature environments)

Young’s Modulus: 100–150 GPa (high stiffness for structural applications)

Fabrication Methods: Stir casting, powder metallurgy, liquid metal infiltration

Surface Finish: Machined, polished, or net-shape (no finish machining required)

Certifications: ISO 9001, ISO 14001, RoHS, REACH

Packaging: Anti-static, vacuum-sealed in Class 100 cleanroom for reliability

Contact Us: Inquire about custom specifications or pricing. Click below to connect with our team.

Standout Features

High Thermal Conductivity – Efficient heat removal for high-power devices.

Low Coefficient of Thermal Expansion (CTE) – Matches semiconductors like Si, SiC, and GaAs to minimize stress.

Lightweight Strength – High stiffness-to-weight ratio for structural reliability.

Corrosion Resistance – Durable in harsh environments.

Design Flexibility – Net-shape castable into complex geometries.

Excellent Mechanical Stability – Maintains dimensional accuracy under thermal cycling.

Applications

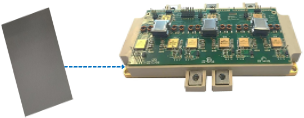

Power Module Baseplates & Housings: For IGBT, SiC, and GaN power modules in electric vehicle inverters and industrial motor drives, where they manage high heat flux and match the CTE of ceramic substrates.

Microprocessor Lids & Heat Spreaders: For high-performance computing CPUs, GPUs, and ASICs in servers and workstations, providing superior thermal dissipation and preventing package warpage.

RF Microwave Housing: For amplifiers and transmit-receive modules in 5G/6G base stations and aerospace radar systems, offering lightweight shielding and thermal stability.

Laser Diode Carriers & Heat Sinks: For high-power laser systems in industrial cutting, medical equipment, and LiDAR, where precise thermal management is critical for wavelength stability.

Spacecraft Avionics Trays & Structures: For housing electronics in satellites, providing a lightweight, stiff, and thermally stable platform that survives launch vibrations and orbital thermal cycling.

Aerothermal Heat Sinks: For avionics and electronics in hypersonic vehicles and military aircraft, capable of withstanding extreme thermal shock and high temperatures.

Electronically Controlled Unit (ECU) Housings: For high-reliability automotive and aerospace control units, offering electromagnetic interference (EMI) shielding and passive cooling.

Photonic & Optical Platform Submounts: For stabilizing and cooling sensitive photonic integrated circuits (PICs) and optical communication components in data centers.

High-Brightness LED Mounting Plates: For industrial lighting and automotive headlights, managing heat to maintain lumen output and longevity.

Nuclear Instrumentation Carriers: For sensors and electronics in nuclear power environments, leveraging AlSiC's radiation resistance and dimensional stability.

Benefits

Reduced Thermal Stress – CTE match minimizes cracking and delamination.

Weight Savings – Lighter than copper while maintaining strength.

Enhanced Device Reliability – Protects components from heat and mechanical strain.

Customizable – Shape, composition, and properties tailored to application needs.

Long Service Life – Resists corrosion, fatigue, and thermal cycling degradation.

Why Choose Us?

Our AlSiC MMCs lead in a competitive market, powered by Singapore’s market agility and Taiwan’s world-class semiconductor expertise. Here’s why global buyers trust us:

Uncompromising Quality: Partnering with Taiwanese foundries, we deliver ISO 9001-certified AlSiC MMCs with tailored SiC content (25–70%), meeting aerospace and semiconductor standards.

Advanced Manufacturing: Stir casting and powder metallurgy with 8-inch wafer compatibility match CPS Technologies’ precision, improving yield by 5–10%.

Reliable Supply Chain: Our Singapore-Taiwan synergy mitigates SiC supply risks, ensuring stability akin to Denka’s global partnerships.

Cost Optimization: Net-shape fabrication and high-volume production reduce costs by up to 20%, addressing buyer concerns about MMC pricing.

Custom Solutions: Tailored SiC volume fractions and CTE (6–10 ppm/K) meet specific project needs, mirroring Materion’s application-specific approach.

Sustainability Focus: Lightweight AlSiC reduce energy consumption in EVs and renewables by 10–15%, supporting green initiatives.

Global Trust: Certified to ISO 9001, ISO 14001, RoHS, and REACH, our MMCs are trusted by OEMs in 50+ countries, backed by Taiwan’s 46% foundry share.

Contact Us: Ready to enhance your systems with our AlSiC MMCs? Click below to request a quote or discuss custom specifications.

Industries Served

Aerospace & Aviation

Defense & Military

Automotive & Electric Vehicles

Telecommunications

Power Electronics

Semiconductor Manufacturing & Packaging

Industrial Automation

Medical Electronics

Avionics

Satellite & Space Systems

Computing & Data Storage

Renewable Energy (Solar & Wind Power)

Consumer Electronics (High-end, high-power)

Rail Transportation

Marine Electronics

LED Lighting (High-power)

Why Choose AlSiC?

Superior Thermal Management: 170–230 W/m·K conductivity ensures reliable heat dissipation in power electronics.

Lightweight Strength: 2.7–3.0 g/cm³ density and 300–500 MPa strength optimize aerospace and EV performance.

Low Thermal Expansion: 6–10 ppm/K CTE minimizes stress in semiconductor packaging.

Cost-Effective Production: Net-shape fabrication reduces costs by 20%, ideal for high-volume applications.

Market Leadership: Aligned with the $413.42 million AlSiC MMC market’s 7.3% CAGR, driving innovation.