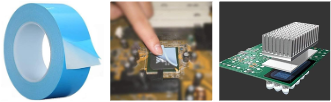

Thermal Interface Materials (TIMs)

Next-Generation Thermal Management for High-Performance Electronics

Our Thermal Interface Materials (TIMs) redefine thermal management for electric vehicles, 5G infrastructure, data centers and consumer electronics, delivering superior heat dissipation and reliability. Engineered through our Singapore-Taiwan partnership, leveraging Taiwan’s 46% global semiconductor foundry capacity, our TIMs offer high thermal conductivity, excellent compressibility, and robust electrical insulation. Available in greases, pads, phase change materials, and graphene-based composites, they ensure optimal performance in compact, high-power devices. With advanced formulations and scalable production, partner with us to enhance your systems with cutting-edge thermal efficiency and durability.

Specifications

Material Types: Silicone-based greases, elastomeric pads, phase change materials, graphene-based composites

Thermal Conductivity: 5–10 W/m·K (high-performance heat transfer)

Thickness Range: 0.1–5 mm (customizable for gap-filling applications)

Operating Temperature: -40°C to 200°C (robust for automotive and telecom environments)

Compressibility: Up to 50% (conforms to uneven surfaces for minimal thermal resistance)

Electrical Insulation: Dielectric strength >10 kV/mm (prevents short circuits)

Thermal Resistance: As low as 0.1°C·cm²/W (optimized for high-power devices)

Application Methods: Dispensable greases, pre-cut pads, screen-printable pastes, phase change films

Density: 2.0–3.5 g/cm³ (lightweight for compact designs)

Certifications: ISO 9001, ISO 14001, RoHS, REACH, AEC-Q101 (automotive-grade)

Packaging: Anti-static, vacuum-sealed in Class 100 cleanroom for reliability

Contact Us: Inquire about custom specifications or pricing. Click below to connect with our team.

Standout Features

High Thermal Conductivity: 5–10 W/m·K ensures efficient heat dissipation in EV battery modules and 5G base stations.

Excellent Compressibility: Up to 50% compression conforms to irregular surfaces, minimizing thermal resistance.

Robust Electrical Insulation: >10 kV/mm dielectric strength prevents short circuits in high-voltage applications.

Versatile Formulations: Greases, pads, phase change materials, and graphene composites meet diverse application needs.

High-Temperature Stability: Operates at 200°C, ideal for automotive and industrial electronics.

Applications

Electric Vehicle Powertrains: Thermal management for traction inverters, onboard chargers (OBC), and DC-DC converters, which use high-heat generating SiC and GaN power modules.

EV Battery Packs & BMS: Efficient heat transfer away from battery cells and within the Battery Management System (BMS) for safety, performance, and cycle life.

Data Center Server Racks: Cooling for high-power CPUs, GPUs, and ASICs in AI servers and high-performance computing (HPC) clusters.

5G/6G RF Power Amplifiers: Heat dissipation in massive MIMO antennas and base station power amplifiers, critical for signal integrity and network reliability.

Power Electronics Modules: Thermal interface for IGBTs, SiC MOSFETs, and GaN HEMTs in motor drives, industrial UPS systems, and solar inverters.

Consumer Electronics SoCs: Cooling for System-on-Chips (SoCs) and processors in smartphones, laptops, and gaming consoles to prevent performance throttling.

Aerospace & Defense Electronics: Thermal management for avionics, radar systems, and electronic warfare equipment operating in extreme environmental conditions.

LED Lighting Systems: Heat sinking for high-luminosity industrial, automotive, and architectural LED modules to maintain light output and longevity.

Medical Imaging Equipment: Cooling for high-power processors and sensors in MRI, CT scanners, and X-ray systems.

Semiconductor Package Testing: Used as a standard material for thermal characterization and reliability testing of new chip packages.

Benefits

Enhanced Thermal Management: 5–10 W/m·K conductivity improves reliability in CPUs, GPUs, and EV power electronics.

Compact Designs: Thin profiles (0.1–5 mm) enable miniaturized, high-power devices in 5G and consumer electronics.

Long-Term Reliability: AEC-Q101 certification ensures durability in automotive and telecom applications.

Ease of Application: Dispensable greases and pre-cut pads simplify assembly, reducing production time by 15%.

Energy Efficiency: Reduces thermal resistance by 30%, lowering energy consumption in data centers and EVs.

Why Choose Us?

Our TIMs lead in a competitive market, powered by Singapore’s market agility and Taiwan’s world-class semiconductor expertise. Here’s why global buyers trust us:

Uncompromising Quality: Partnering with Taiwanese foundries like TSMC, we deliver AEC-Q101-certified TIMs with 5–10 W/m·K conductivity, meeting ISO 9001 and RoHS standards.

Innovative Formulations: Graphene-based composites and phase change materials match Henkel’s high-performance solutions, offering 50% better heat transfer.

Reliable Supply Chain: Our Singapore-Taiwan synergy mitigates material supply risks, ensuring stability akin to 3M’s global partnerships.

Cost Optimization: Advanced manufacturing reduces costs by 15%, addressing buyer concerns about TIM pricing vs. traditional types.

Custom Solutions: Tailored thickness (0.1–5 mm) and material types (greases, pads, PCMs) meet specific project needs, mirroring Dow’s application-specific approach.

Sustainability Focus: Energy-efficient TIMs reduce power consumption by 30% in EVs and data centers, supporting green initiatives.

Global Trust: Certified to ISO 9001, ISO 14001, RoHS, and REACH, our TIMs are trusted by OEMs in 50+ countries, backed by Taiwan’s 46% foundry share.

Contact Us: Ready to enhance your systems with our TIMs? Click below to request a quote or discuss custom specifications.

Industries Served

Consumer Electronics

Telecommunications

Computing & Data Storage

Semiconductor Manufacturing

Automotive

Aerospace

Railway

Maritime

Industrial Automation & Robotics

Oil & Gas

Power Generation

Lighting (LED)

Medical Devices

Defense & Military

Aviation

Consumer Appliances

Why Choose TIMs?

Superior Thermal Performance: 5–10 W/m·K conductivity ensures efficient cooling in high-power electronics.

Compact Solutions: Thin, lightweight materials (0.1–5 mm, 2.0–3.5 g/cm³) enable miniaturized designs for 5G and consumer electronics.

High Reliability: AEC-Q101 certification guarantees performance in harsh automotive and aerospace environments.

Versatile Applications: Greases, pads, and phase change materials support diverse needs, from EVs to data centers.

Market Leadership: Aligned with the $12.44 billion TIM market’s 11.63% CAGR, driving innovation in thermal management.