GALLIUM NITRIDE (GaN) WAFERS

Unleashing High-Power Innovation

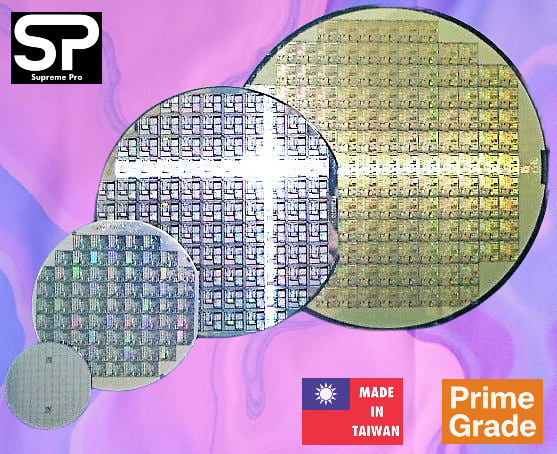

Image shown is a representation only. Exact specifications should be obtained from the product data sheet.Gallium Nitride (GaN) wafers are pivotal in power electronics and RF applications, driven by demand in electric vehicles (EVs), 5G telecommunications, and data centers. Classified as a compound semiconductor, our GaN wafers are at the forefront of next-generation power and RF electronics, delivering unparalleled efficiency and performance. Engineered through our Singapore-Taiwan partnership, leveraging Taiwan’s 60% global semiconductor dominance, our GaN-on-Si and GaN-on-SiC wafers offer high electron mobility, wide band gap, and superior thermal conductivity. Designed for automotive-grade reliability, they enable compact, energy-efficient solutions for EVs, 5G infrastructure, and data centers. Partner with us to power your high-frequency, high-voltage applications with cutting-edge technology.

Our GaN Wafers

2-inch GaN-on-Si Epitaxial Wafer

2-inch GaN Template Wafer on Sapphire

4-inch (100mm) GaN-on-Si Epitaxial Wafer

4-inch (100mm) GaN-on-SiC Epitaxial Wafer

6-inch (150mm) GaN-on-Si Epitaxial Wafer

6-inch (150mm) GaN-on-SiC Epitaxial Wafer

8-inch (200mm) GaN-on-Si Epitaxial Wafer

8-inch (200mm) GaN Template Wafer on SiC

+ We offer fully customizable GaN wafers and substrates to suit your unique needs, including specialized epitaxial options. Contact us today for a personalized quote and explore how our tailored solutions can elevate your projects.

WHY CHOOSE GaN WAFERS?

High Performance

GaN’s wide band gap and high electron mobility enable 100x faster switching, ideal for 5G and EV markets.

Cost Efficiency

Scalable 300mm wafers reduce production costs by 2.3x compared to 200mm, nearing silicon cost parity.

Reliability

Low dislocation density (≤10⁸/cm²) and AEC-Q100 compliance ensure consistent performance in critical applications.

Compact Solutions

High power density supports 50% smaller devices, meeting demand for lightweight EV and consumer electronics.

Future-Proof

Aligned with the $20.11 billion GaN market’s 22.7% CAGR, our wafers drive innovation in AI, 5G, and renewables.

WHY CHOOSE US?

Superior Quality

Leveraging Taiwan’s 60% global chip share, we deliver Prime Grade 4H-GaN wafers with dislocation density ≤10⁸/cm², meeting stringent AEC-Q100 standards for automotive and aerospace applications.

Cost Efficiency

Our focus on yield optimization (up to 85% in 2026 scenarios) and reusable wafer technologies reduces costs by up to 30%, addressing buyer concerns about GaN’s high cost vs. silicon.

Custom Solutions

We offer tailored wafer specifications (e.g., doping, thickness) and dedicated support, matching key player’s customer-centric approach, to meet unique project needs.

Sustainability Focus

Our GaN wafers enable energy-efficient devices, reducing EV ownership costs by ~$4,000 and supporting decarbonization, aligning with buyer priorities for green technology.

Advanced Manufacturing

Partnering with Taiwanese leaders in this sector, we use cutting-edge PVT and CVD processes to ensure low-defect, high-uniformity wafers, scalable to 200mm for cost-efficient production.

Reliable Supply Chain

Unlike competitors facing 20% supply shortages, our vertically integrated supply chain, inspired by STMicroelectronics’ Catania campus, ensures consistent delivery and extended longevity programs.

Global Trust

Certified to ISO 9001, ISO 14001, RoHS, and REACH standards, our wafers are trusted by OEMs in 45+ countries, backed by Singapore-Taiwan expertise.

Ready to elevate your designs with our GaN Wafers? Click below to request a quote or discuss custom specifications.

SPECIFICATIONS

Material: GaN-on-Si (primary), GaN-on-SiC, GaN-on-Sapphire (custom options)

Diameter: 100mm, 150mm, 200mm (scalable for high-volume production)

Thickness: 400–650 µm (customizable per application)

Dislocation Density: ≤10⁸/cm² (low-defect for high reliability)

Surface Finish: Metal Organic Chemical Vapor Deposition (MOCVD), mirror-like, Ra <0.5 nm

Doping: N-type (Si-doped) or P-type (Mg-doped) for power and RF applications

Thermal Conductivity: 130–200 W/m·K (GaN-on-SiC), 50–70 W/m·K (GaN-on-Si)

Breakdown Electric Field: 3.3 MV/cm (10x silicon)

Bandgap: 3.4 eV (3x silicon for high-temperature operation)

Electron Mobility: 1,500–2,000 cm²/V·s (2x silicon for faster switching)

Crystal Structure: Wurtzite, optimized for HEMTs and power devices

Packaging: Class 100 cleanroom, vacuum-sealed for contamination-free delivery

Contact Us: Inquire about custom specifications or pricing. Click below to connect with our team.

STANDOUT FEATURES

Superior Thermal Conductivity

130–200 W/m·K (GaN-on-SiC) dissipates heat efficiently, enhancing device lifespan in high-power systems.

Wide Band Gap

3.4 eV supports high-voltage operation (up to 600V), reducing cooling needs for compact designs.

Lower Capacitance

Up to 90% reduced parasitic capacitance (8-inch wafers) enhances high-frequency performance.

Advanced Surface Quality

CMP delivers a mirror-like finish (Ra <0.5 nm), ensuring optimal epitaxial layer growth for high-performance devices.

Scalable Wafer Sizes

100mm to 300mm diameters, with 300mm offering 2.3x more chips per wafer, reducing costs.

High Electron Mobility

1,500–2,000 cm²/V·s enables ultra-fast switching, ideal for 5G RF amplifiers and EV chargers.

High Breakdown Field

3.3 MV/cm (10x silicon) ensures robust performance in high-voltage EV and 5G applications.

Low Dislocation Density

≤10⁸/cm² ensures high reliability and yield, critical for automotive and defense applications.

ADDITIONAL BENEFITS

Enhanced Efficiency

Up to 40% energy savings in power supplies, reducing operating costs in data centers and EVs.

Thermal Resilience

Operates at temperatures up to 400°C, ensuring reliability in aerospace and industrial applications.

Compact Designs

High power density enables 50% smaller chargers and inverters, cutting EV production costs by ~$1,500 per vehicle.

Contact Us: Discover how our GaN wafers can optimize your designs. Click below for a quote.

High-Frequency Performance

100x faster switching speeds support 5G base stations and radar systems, improving signal reliability.

Sustainability

GaN’s efficiency reduces carbon emissions by 10x compared to silicon, supporting green initiatives.

INDUSTRIES, APPLICATIONS & SYSTEMS USING GaN WAFERS

Power Electronics

GaN HEMTs (High Electron Mobility Transistors)

GaN Power Switches / High-Efficiency Switches

GaN Inverters & Power Converters

GaN Power Modules

GaN High-Voltage Transistors & Switches

GaN Power Management Units (PMUs)

GaN High-Power Rectifiers

GaN High-Voltage Power Supplies

Electric Vehicle (EV) Powertrains

On-Board Chargers (OBC)

Battery Management Systems (BMS)

Vehicle-to-Everything (V2X) Communication Modules

Aircraft Radar Systems (Airborne AESA Radars)

Spacecraft Power Management Units (PMUs)

Space Exploration Electronics (Deep-Space Communication, Power Systems)

Satellite Communication Payloads

Satellite Broadband Networks

Radar Systems (Ground, Naval & Airborne)

Military Communication Systems

Missile Defense Radar & Guidance Systems

5G Base Stations (RF Power Amplifiers, Small Cells)

Industries

Electric Vehicles

Aerospace

Defense

Telecommunications

Data Centers

Renewable Energy

Sensors & Harsh-Environment Devices

GaN High-Temperature Transistors / Components

GaN High-Temperature Sensors

GaN Corrosion-Resistant Sensors

GaN Radiation-Hardened / Radiation-Resistant Devices

GaN High-Frequency Sensors

Systems / Devices

Power Grids

Industrial & Automation

Consumer Electronics

Medical

Research & Development

Applications

RF & Microwave Devices

GaN RF Transistors

GaN Power Amplifiers

GaN RF Modules

GaN High-Frequency Amplifiers / Oscillators

GaN High-Power Microwave Devices

GaN Electronic Warfare Components

GaN High-Frequency Devices & Test Structures

Optoelectronics

GaN LEDs (Light-Emitting Diodes)

GaN Optoelectronic Components

Wireless Communication Infrastructure (Microwave & mmWave Systems)

Data Center Servers (Power Supplies, Cooling Subsystems)

High-Speed Computing Systems (AI Accelerators, HPC Servers)

Solar Inverters

Wind Turbine Power Conversion Systems

Energy Storage Unit (ESS) Converters

Smart Grid Infrastructure

Renewable Energy Integration Systems

Power Distribution Networks

Industrial Motor Drives

Factory Automation Systems

Robotics Power Electronics

At Supreme Pro, we offer fully customizable GaN wafers and substrates to suit your unique needs, including specialized epitaxial options. Contact us today for a personalized quote and explore how our tailored solutions can elevate your projects.

Research Applications

GaN Quantum Electronics Substrates

GaN Experimental Devices

Heavy-Duty Industrial Equipment

Mining Machinery

Offshore Platform Electronics (Oil & Gas)

Downhole Monitoring Systems

Chemical Reactor Power Systems

Process Control Units

Smartphones (Fast Charging Circuits, RF Front-End Modules)

Medical Imaging Devices (Ultrasound, CT, MRI Power Systems)

Portable Diagnostic Equipment

Radiation Therapy Machines

University Laboratory Systems

Innovation Centers

Technology R&D Facilities

Our GaN Wafers

2-inch GaN-on-Si Epitaxial Wafer

2-inch GaN Template Wafer on Sapphire

4-inch (100mm) GaN-on-Si Epitaxial Wafer

4-inch (100mm) GaN-on-SiC Epitaxial Wafer

6-inch (150mm) GaN-on-Si Epitaxial Wafer

6-inch (150mm) GaN-on-SiC Epitaxial Wafer

8-inch (200mm) GaN-on-Si Epitaxial Wafer

8-inch (200mm) GaN Template Wafer on SiC